In recent years, transparent LED film displays have transformed how businesses and architects use glass surfaces. These ultra-thin, flexible, and adhesive transparent LED film turn ordinary glass into dynamic digital displays—without blocking natural light or requiring bulky hardware. But one of the most common questions from designers and project planners is: Can adhesive transparent LED film be custom made?

The answer is a definite yes. Modern LED film technology allows for extensive customization, covering size, shape, resolution, brightness, and even curvature. In this article, we’ll explore how these films can be tailored to your project, what customization options are available, and what you should consider when ordering a custom solution.

What Is adhesive transparent LED film?

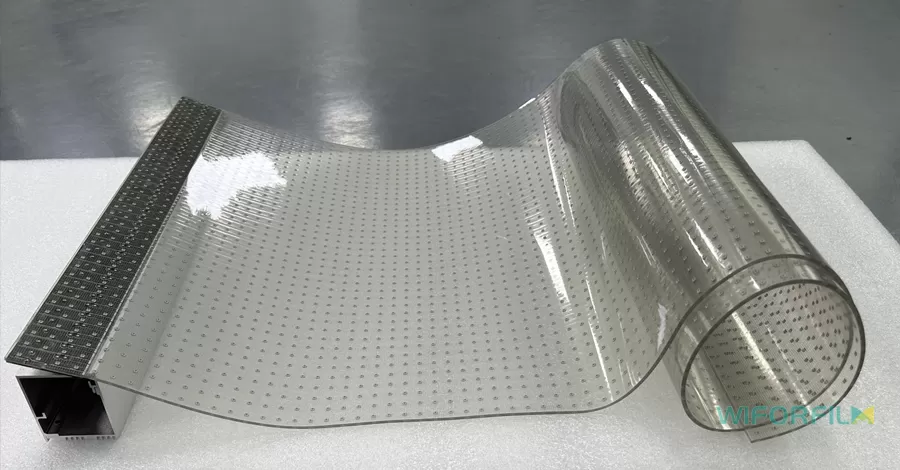

Adhesive transparent LED film is a new-generation display technology that uses ultra-thin LED chips embedded in a flexible, transparent substrate. It can be directly attached to glass or other smooth surfaces using a self-adhesive backing. Once installed, the film turns the surface into a see-through digital screen—displaying videos, animations, or static images—while maintaining high transparency and visibility.

This technology is popular for storefront windows, architectural façades, shopping malls, museums, corporate lobbies, and exhibitions, offering a sleek and futuristic way to communicate visually.

Why Customization Matters

No two glass installations are the same. Retail stores, corporate offices, and creative installations often have unique glass dimensions, shapes, and lighting conditions. That’s why customization plays a critical role in adhesive LED film projects.

Manufacturers now provide a wide range of custom options, enabling you to align the product perfectly with your design vision. Whether you need to cover an entire glass wall or fit around a curved window, custom LED film ensures a seamless, professional result.

Customization Options Available

1. Size and Shape

One of the greatest advantages of LED film is its modularity. Each panel can be cut or arranged to match specific dimensions. Manufacturers can custom-cut the film to fit large glass walls, small windows, or even irregular shapes.

For curved glass or creative structures, flexible LED films can bend to match the surface, maintaining both the display quality and the transparency effect.

2. Pixel Pitch and Resolution

Pixel pitch (P4, P5, P6.25, P8, P10, etc.) defines the distance between individual LEDs. Smaller pixel pitch values mean higher resolution and sharper images. When customizing your film, you can choose a pitch that balances image clarity and transparency. For example, a retail window may choose P6.25 for detailed visuals, while a large outdoor installation might prefer P10 for greater light transmission.

3. Brightness and Transparency Levels

Brightness can be customized to suit indoor or outdoor environments. Outdoor glass façades require higher brightness for visibility in daylight, while indoor films can use lower brightness to maintain visual comfort. Transparency levels can reach up to 95%, ensuring the display remains nearly invisible when turned off.

4. Adhesive and Mounting Options

Adhesive transparent LED film is typically self-sticking, eliminating heavy frames or metal structures. However, the adhesive type can be adjusted based on your glass surface—standard glass, laminated glass, or curved panels. Some versions use a removable adhesive for temporary displays, while others are designed for permanent installation.

5. Curvature Support

Not all projects involve flat glass. Flexible LED films are specifically engineered to handle gentle curves, allowing designers to apply them on rounded surfaces such as cylindrical columns or curved storefronts. Custom models can even be built to match the radius of your design.

6. Control Systems and Connectivity

Manufacturers also offer custom control solutions—from USB and Wi-Fi systems to cloud-based content management platforms. Depending on your project, you can integrate the display into a building’s automation system or manage it remotely.

How Manufacturers Deliver Custom Solutions

When you request a custom adhesive transparent LED film, the process usually follows these steps:

- Design Consultation: You share your project details—glass dimensions, curvature, environment (indoor/outdoor), and display requirements.

- Prototype or Layout Design: The manufacturer provides a CAD layout or prototype to visualize how the film will be applied.

- Production: Custom panels are manufactured, calibrated for pixel alignment, brightness, and transparency.

- Installation and Testing: Technicians assist with applying the film, connecting data cables, and testing visual performance.

Brands like WIFORFILM, and REEFILM offer such tailored services. Whether it’s a small indoor display or a massive architectural installation, these companies can customize the product’s specifications to meet your vision.

Final Thoughts

So, can adhesive transparent LED film be custom made?

Absolutely.

With modern technology, nearly every aspect of these films—from size and shape to resolution and brightness—can be tailored to your exact needs. This flexibility opens up endless possibilities for architects, retailers, and designers to transform glass into interactive, light-filled digital canvases.

Whether you’re creating a futuristic storefront, an immersive exhibition, or a modern corporate façade, custom adhesive transparent LED film provides a seamless, elegant way to blend architecture with digital innovation.

Associated Products

You may also be interested in the following products:

Self-Adhesive Transparent LED Display Film - P5

Transparent LED Film Display Screen - P6.25

Flexible LED Transparent Film Screen - P8

Ultra Transparent Film LED Screen

Transparent Flexible Film Screen - P15

LED Crystal Film Screen

Transparent LED Screen Film - P4