As someone who has spent years working with display technologies—from traditional LED panels to the new generation of transparent and flexible LED film screens—I’m often asked one question: “How durable are LED film screens, really?”

It’s a fair question. These screens promise architectural freedom, stunning transparency, and ultra-thin profiles—but unlike the solid aluminum frames of classic LED cabinets, LED film seems delicate at first glance. After studying multiple installations, lab test data, and long-term field results from manufacturers across Asia, Europe, and North America, I can say with confidence: LED film screens are far more robust than they appear—if they’re designed and installed correctly.

1. Understanding What “Durability” Means for LED Film

When we talk about durability in this context, we’re not only asking how long the LEDs light up. Durability covers:

- Electrical stability: how long the LED chips, interconnects, and drivers continue to function.

- Optical stability: how brightness and color hold up over time.

- Mechanical integrity: whether the film remains adhered to glass or other surfaces without peeling or cracking.

- Environmental resistance: how well the system tolerates heat, humidity, UV exposure, and dust.

The key challenge is that LED film integrates electronics into a flexible, transparent substrate—often PET or similar polymer—laminated with conductive circuits. It’s a remarkable engineering balance between visibility and protection.

2. Typical Lifespan: Between Theory and Reality

Most major manufacturers, from Luxmage to Unilumin and Radiant, quote a lifespan of 50,000 to 100,000 hours for LED film screens. In practice, that translates to 8–10 years of service life under normal operating conditions.

However, this number deserves context. The industry standard “lifetime” usually refers to the period until the display’s brightness falls to 50% of its initial level (known as L50). The screen still functions beyond that point—it’s simply dimmer.

So, when a spec sheet promises 100,000 hours, that doesn’t mean zero failure before that moment; rather, it indicates a predictable degradation curve where color uniformity and brightness slowly decline.

From field observations, high-quality LED films operating indoors at moderate brightness often exceed a decade of service. Outdoor or high-humidity environments, on the other hand, can shorten that by several years if the film is not properly sealed.

3. What Actually Limits LED Film Lifespan?

Based on testing reports and failure analyses I’ve reviewed, the durability of LED film is governed by a combination of materials science and environmental stress. The main factors include:

a) LED Chip Quality and Drive Current

High-efficiency, low-current LED chips last significantly longer. Overdriving the LEDs for higher brightness accelerates electromigration and thermal fatigue. Operating at 70–80% of rated brightness can easily double lifetime.

b) Encapsulation and Moisture Protection

Moisture is the silent killer of LED films. Humid air can corrode the microelectrodes or oxidize solder joints. I’ve seen installations in coastal regions fail within three years simply due to inadequate sealing.

Modern LED films combat this with multi-layer encapsulation—a combination of epoxy, silicone, or polyurethane coatings, plus high-quality adhesives between film and glass. Units that achieve IP65 or higher water/dust resistance are considerably more reliable.

c) Adhesive Aging and UV Resistance

The adhesive that bonds LED film to the substrate is often overlooked. UV exposure and heat cause certain adhesives to yellow, crack, or lose adhesion over time. Good formulations use UV-stabilized polymers that maintain clarity for years.

d) Thermal Management

Even transparent films generate heat. While their power density is lower than full LED cabinets, the lack of a heavy aluminum frame means heat must dissipate through the glass or ambient air.

Thermal cycling—from hot days to cool nights—induces mechanical stress. Manufacturers test for this using 1,000-cycle thermal shock protocols between –20 °C and +60 °C. Films that pass such testing tend to maintain performance well beyond five years.

e) Environmental and Mechanical Stress

LED film is thin—often less than 3 mm—and can be bent or flexed. However, repeated mechanical stress, vibration, or improper installation can crack traces or delaminate layers. For fixed architectural applications, mechanical stability is usually excellent; for mobile or rental use, the risks are higher.

4. Testing Durability: Beyond Marketing Claims

Many vendors now subject LED films to accelerated aging tests that simulate years of exposure in weeks or months:

- 85 °C / 85% RH tests to simulate tropical humidity.

- Salt spray tests for coastal environments.

- UV exposure chambers for outdoor façades.

- Thermal shock cycling for regions with wide temperature swings.

For example, Radiant reports less than 5% brightness degradation after 1,000 hours at 85% humidity and 40 °C—an impressive figure that aligns with long-term stability data from transparent OLEDs and other display polymers.

5. Indoor vs. Outdoor Durability

Indoor Applications

Indoor LED films—mounted behind glass in malls, offices, or exhibition halls—are the most durable. They avoid UV and rain exposure, operate at moderate brightness, and benefit from stable indoor climates.

In such conditions, failures are rare, mostly limited to individual diodes or localized discoloration after 8–10 years.

Outdoor Applications

Outdoor installations face UV radiation, temperature extremes, and moisture. Here, the quality of encapsulation and the integration with glass make or break the product.

Well-sealed outdoor films can still exceed five years of stable operation, but cheap variants without UV protection or with poor adhesives degrade quickly—sometimes showing yellowing, flickering, or partial delamination within two years.

6. Maintenance: The Often-Ignored Durability Factor

Even the most robust LED film can fail prematurely without proper care. Regular maintenance—mainly cleaning dust, checking for peeling edges, and ensuring electrical connectors remain dry—dramatically extends lifespan.

Since LED film is modular, replacing small sections is feasible without removing the entire display. I always recommend choosing film with easy-replaceable light strips or tiles, allowing for partial repairs instead of total replacement.

7. The Role of Installation Quality

In my field work, I’ve observed that installation errors are responsible for nearly half of premature failures. Common issues include:

- Poor adhesion due to dirty glass surfaces.

- Trapped moisture during lamination.

- Bending radius violations during mounting.

- Incorrect voltage or grounding causing electrostatic discharge.

Proper installation—by trained technicians using controlled environments—can easily double the effective service life of the product.

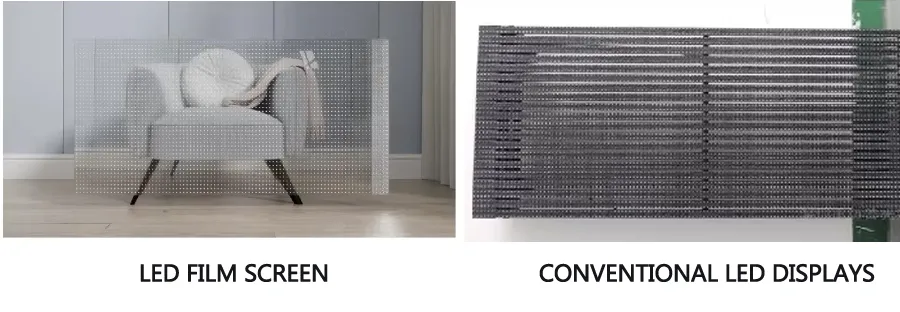

8. Comparing LED Film with Conventional LED Displays

It’s tempting to think of LED film as a “fragile” alternative to solid cabinets, but the data tell a different story. Traditional LED modules, with their metal housings and active cooling, indeed handle outdoor abuse better. Yet LED film has its own strengths:

| Property | LED Film | Conventional LED Cabinet |

|---|---|---|

| Transparency | Up to 90% | 0% |

| Weight | ~1–2 kg/m² | 25–30 kg/m² |

| Flexibility | High | None |

| Durability (indoor) | Excellent (8–10 yrs) | Excellent (8–10 yrs) |

| Durability (outdoor) | Moderate to good (3–6 yrs) | Excellent (5–10 yrs) |

| Maintenance | Easy replacement of strips | Modular cabinet repair |

| Vulnerabilities | Adhesive aging, UV | Dust, heat, heavy weight |

So while LED film may not replace every type of LED wall, it opens design possibilities that conventional panels never could—without necessarily compromising long-term reliability.

9. Practical Strategies to Maximize Durability

From both testing and experience, here are proven ways to extend the lifespan of LED film screens:

- Select high-quality film from reputable suppliers with verified environmental testing (thermal, humidity, UV).

- Use professional installation, ensuring glass cleaning, air-free lamination, and proper sealing.

- Avoid full-brightness operation—set brightness to 70–80% of maximum.

- Monitor temperature and avoid direct sunlight if possible.

- Inspect regularly for signs of delamination, discoloration, or flicker.

- Replace damaged sections promptly to prevent cascading failure.

Following these steps, I’ve seen installations remain pristine for a decade or longer, even in commercial buildings with continuous daily operation.

10. Conclusion: A Mature Technology Ready for the Long Run

After years of skepticism, LED film has proven itself as a reliable display medium—both technically and aesthetically. Its combination of flexibility, transparency, and light weight makes it ideal for integration into glass façades, retail windows, and modern architecture.

Is it as indestructible as a solid-state LED wall? No. But when properly engineered and installed, its durability rivals traditional LEDs, with lifespans comfortably exceeding 100,000 hours and degradation curves well understood by engineers.

In other words: the elegance of LED film does not come at the cost of reliability. The key lies in design discipline, material quality, and respect for physics—principles that apply to every advanced technology we build.

Associated Products

You may also be interested in the following products:

Self-Adhesive Transparent LED Display Film - P5

Transparent LED Film Display Screen - P6.25

Flexible LED Transparent Film Screen - P8

Ultra Transparent Film LED Screen

Transparent Flexible Film Screen - P15

LED Crystal Film Screen

Transparent LED Screen Film - P4